What are the latest resistor factory equipment components procurement models?

What are the Latest Resistor Factory Equipment Components Procurement Models?

I. Introduction

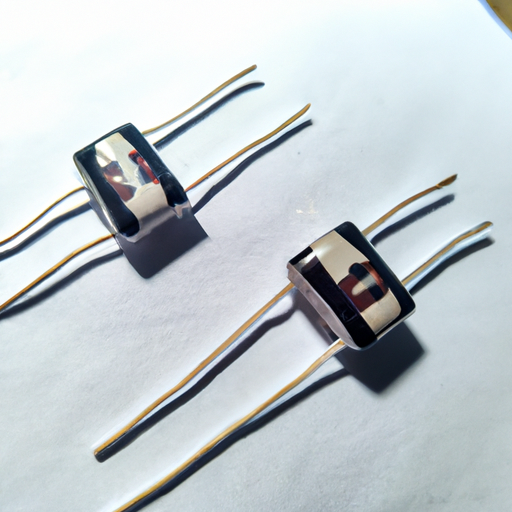

The resistor manufacturing industry plays a crucial role in the electronics sector, providing essential components for a wide range of applications, from consumer electronics to industrial machinery. As technology advances and market demands evolve, the procurement models used in resistor manufacturing have also undergone significant changes. Effective procurement is vital for optimizing operations, reducing costs, and ensuring the timely availability of high-quality components. This article aims to explore the latest procurement models for resistor factory equipment components, highlighting traditional methods, emerging trends, and the importance of sustainability and data-driven approaches.

II. Understanding Procurement Models

Procurement models refer to the strategies and processes organizations use to acquire goods and services. In manufacturing, procurement is not merely about purchasing; it encompasses a comprehensive approach to sourcing, supplier management, and logistics. Key components of procurement models include supplier selection, negotiation strategies, contract management, and performance evaluation. Understanding these components is essential for manufacturers to streamline operations and enhance competitiveness.

III. Traditional Procurement Models

A. Overview of Traditional Procurement Methods

Traditional procurement methods, such as Request for Proposal (RFP) and Request for Quotation (RFQ), have been the backbone of sourcing strategies for many years.

1. **Request for Proposal (RFP)**: This method involves soliciting proposals from suppliers to provide detailed information about their capabilities, pricing, and terms. RFPs are typically used for complex projects where multiple factors beyond price are considered.

2. **Request for Quotation (RFQ)**: RFQs are more straightforward and focus primarily on price. Manufacturers send out RFQs to potential suppliers to obtain competitive quotes for specific components or services.

B. Advantages and Disadvantages of Traditional Models

While traditional procurement methods have their advantages, such as structured processes and clear documentation, they also come with disadvantages. The lengthy timelines associated with RFPs and RFQs can delay production schedules, and the reliance on manual processes can lead to inefficiencies.

C. Limitations in the Context of Resistor Manufacturing

In the fast-paced world of resistor manufacturing, traditional procurement models may struggle to keep up with the demand for agility and responsiveness. The limitations of these models can hinder a manufacturer’s ability to adapt to changing market conditions and technological advancements.

IV. Emerging Procurement Models

A. Just-in-Time (JIT) Procurement

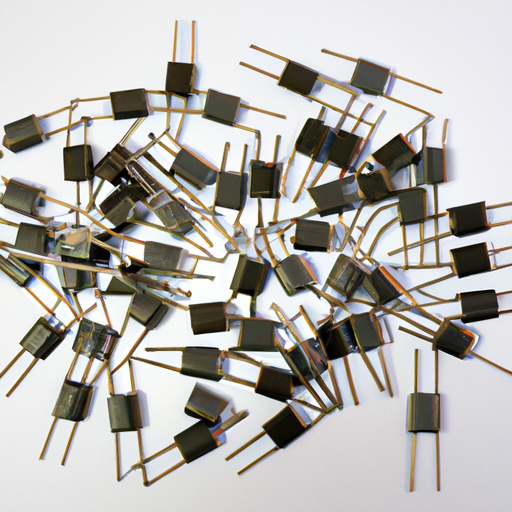

1. **Definition and Principles**: Just-in-Time (JIT) procurement is a strategy that aims to reduce inventory costs by receiving goods only as they are needed in the production process. This model emphasizes efficiency and waste reduction.

2. **Benefits for Resistor Manufacturing**: JIT procurement can significantly benefit resistor manufacturers by minimizing excess inventory, reducing storage costs, and improving cash flow. It allows manufacturers to respond quickly to changes in demand without overcommitting resources.

3. **Challenges and Considerations**: However, JIT procurement requires a high level of coordination with suppliers and can be vulnerable to supply chain disruptions. Manufacturers must carefully assess their supply chain resilience when implementing this model.

B. Collaborative Procurement

1. **Definition and Framework**: Collaborative procurement involves multiple organizations working together to leverage their collective purchasing power. This model fosters partnerships and alliances among manufacturers, suppliers, and even competitors.

2. **Role of Partnerships and Alliances**: In the resistor manufacturing sector, collaborative procurement can lead to better pricing, shared resources, and improved innovation. By pooling resources, companies can negotiate better terms and access a wider range of suppliers.

3. **Case Studies in Resistor Manufacturing**: Several resistor manufacturers have successfully implemented collaborative procurement strategies, resulting in cost savings and enhanced product quality. These partnerships often lead to shared research and development efforts, driving innovation in the industry.

C. E-Procurement Solutions

1. **Definition and Technology Integration**: E-procurement refers to the use of digital platforms and tools to facilitate the procurement process. This includes online marketplaces, procurement software, and electronic invoicing systems.

2. **Benefits of Digital Procurement Platforms**: E-procurement solutions streamline the procurement process, reduce paperwork, and enhance transparency. They enable manufacturers to access a broader range of suppliers and make data-driven decisions.

3. **Examples of E-Procurement Tools in Use**: Many resistor manufacturers are adopting e-procurement tools such as SAP Ariba, Coupa, and Jaggaer to optimize their procurement processes. These platforms offer features like supplier management, contract tracking, and spend analysis.

V. Sustainable Procurement Models

A. Definition and Importance of Sustainability in Procurement

Sustainable procurement focuses on acquiring goods and services in a way that minimizes environmental impact and promotes social responsibility. In the resistor manufacturing industry, sustainability is becoming increasingly important as consumers and regulators demand more eco-friendly practices.

B. Green Procurement Practices in Resistor Manufacturing

Green procurement practices involve sourcing materials and components that are environmentally friendly, such as those made from recycled materials or produced using sustainable methods. Resistor manufacturers are increasingly adopting these practices to reduce their carbon footprint and enhance their brand reputation.

C. Case Studies of Companies Implementing Sustainable Procurement

Several leading resistor manufacturers have successfully integrated sustainable procurement into their operations. For example, companies that prioritize sourcing from suppliers with strong environmental credentials have reported improved customer loyalty and reduced operational risks.

VI. Data-Driven Procurement Models

A. Role of Data Analytics in Procurement

Data analytics plays a crucial role in modern procurement models. By leveraging data, manufacturers can gain insights into supplier performance, market trends, and cost structures, enabling more informed decision-making.

B. Predictive Analytics and Its Application in Resistor Manufacturing

Predictive analytics involves using historical data to forecast future trends. In resistor manufacturing, this can help companies anticipate demand fluctuations, optimize inventory levels, and identify potential supply chain disruptions.

C. Benefits of Data-Driven Decision-Making in Procurement

Data-driven procurement models enhance efficiency, reduce costs, and improve supplier relationships. By making decisions based on data rather than intuition, manufacturers can achieve better outcomes and drive continuous improvement.

VII. Supplier Relationship Management (SRM)

A. Importance of SRM in Procurement

Supplier Relationship Management (SRM) is a strategic approach to managing interactions with suppliers. Effective SRM is essential for fostering collaboration, ensuring quality, and driving innovation in the procurement process.

B. Strategies for Effective Supplier Relationship Management

Manufacturers can implement various strategies to enhance SRM, including regular communication, performance evaluations, and joint development initiatives. Building strong relationships with suppliers can lead to better pricing, improved quality, and increased responsiveness.

C. Impact of SRM on Procurement Efficiency and Quality

A robust SRM strategy can significantly improve procurement efficiency and product quality. By working closely with suppliers, manufacturers can identify opportunities for cost savings, innovation, and process improvements.

VIII. Future Trends in Procurement Models

A. Automation and AI in Procurement

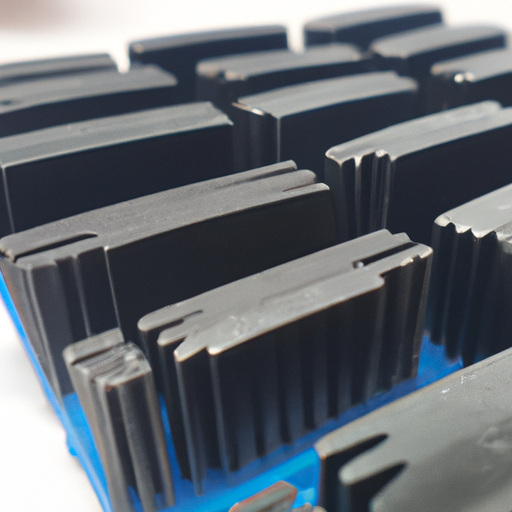

The integration of automation and artificial intelligence (AI) in procurement processes is a growing trend. These technologies can streamline repetitive tasks, enhance data analysis, and improve decision-making.

B. Blockchain Technology and Its Implications

Blockchain technology has the potential to revolutionize procurement by providing transparent and secure transaction records. In the resistor manufacturing industry, blockchain can enhance traceability, reduce fraud, and improve supplier accountability.

C. The Shift Towards Circular Economy Models

The circular economy model emphasizes sustainability and resource efficiency. As manufacturers increasingly adopt circular practices, procurement strategies will need to evolve to support the reuse and recycling of materials.

IX. Conclusion

In conclusion, the procurement landscape in the resistor manufacturing industry is rapidly evolving. Traditional procurement models are being supplemented and, in some cases, replaced by emerging strategies that prioritize efficiency, collaboration, sustainability, and data-driven decision-making. As manufacturers adapt to these changes, they will be better positioned to meet the demands of a dynamic market and drive innovation in their operations. Embracing new procurement models is not just a trend; it is essential for long-term success in the competitive world of resistor manufacturing.

X. References

A comprehensive list of academic papers, industry reports, and other resources used in the article would be included here to support the information presented and provide further reading for interested readers.