What are the product characteristics of automotive resistors?

What are the Product Characteristics of Automotive Resistors?

I. Introduction

Automotive resistors are essential components in the electrical systems of vehicles, playing a critical role in managing electrical currents and ensuring the proper functioning of various automotive applications. These resistors help regulate voltage, control current flow, and protect sensitive electronic components from damage. As vehicles become increasingly sophisticated, understanding the characteristics of automotive resistors is vital for engineers, manufacturers, and automotive enthusiasts alike. This article will explore the different types of automotive resistors, their key characteristics, material composition, packaging, reliability, applications, and future trends.

II. Types of Automotive Resistors

A. Fixed Resistors

Fixed resistors are the most common type of resistors used in automotive applications. They have a predetermined resistance value that does not change. These resistors are typically used in applications where a constant resistance is required, such as in voltage dividers, current limiting, and biasing circuits. Common applications in vehicles include power distribution systems, lighting circuits, and electronic control units (ECUs).

B. Variable Resistors

Variable resistors, also known as potentiometers or rheostats, allow for adjustable resistance values. This flexibility makes them ideal for applications where tuning or calibration is necessary. In automotive settings, variable resistors are often used in applications such as volume controls in audio systems, throttle position sensors, and climate control systems.

C. Specialty Resistors

Specialty resistors include components like thermistors and photoresistors, which have unique properties that make them suitable for specific applications. Thermistors are temperature-sensitive resistors that change resistance with temperature variations, making them ideal for temperature sensing and control in automotive systems. Photoresistors, on the other hand, change resistance based on light exposure and are often used in automatic lighting systems.

III. Key Characteristics of Automotive Resistors

A. Resistance Value

The resistance value of a resistor is a fundamental characteristic that determines how much current will flow through it when a voltage is applied. Measured in ohms (Ω), the resistance value is crucial in circuit design, as it affects the overall performance and functionality of the electrical system. In automotive applications, selecting the correct resistance value is essential for ensuring that components operate within their specified limits.

B. Power Rating

The power rating of a resistor indicates the maximum amount of power it can dissipate without overheating. Measured in watts (W), the power rating is significant for performance and safety. In automotive applications, resistors must be able to handle the power generated by the electrical system, especially in high-load scenarios. Choosing a resistor with an appropriate power rating is critical to prevent failure and ensure reliability.

C. Tolerance

Tolerance refers to the allowable deviation from the specified resistance value. It is expressed as a percentage and indicates how much the actual resistance can vary from the nominal value. In automotive applications, tight tolerance levels are often required to ensure precise control and functionality. For example, sensors and control circuits may need resistors with low tolerance to maintain accuracy.

D. Temperature Coefficient

The temperature coefficient of a resistor indicates how its resistance changes with temperature. This characteristic is particularly relevant in automotive environments, where temperature fluctuations can be significant. A low temperature coefficient is desirable, as it ensures that the resistor maintains stable performance across a wide temperature range, which is crucial for the reliability of automotive systems.

E. Voltage Rating

The voltage rating of a resistor indicates the maximum voltage that can be applied across it without causing breakdown or failure. In automotive electrical systems, where voltages can vary significantly, selecting resistors with appropriate voltage ratings is essential to prevent damage and ensure safe operation.

IV. Material Composition

A. Common Materials Used in Automotive Resistors

The material composition of automotive resistors significantly impacts their performance and durability. Common materials include:

1. **Carbon Composition**: These resistors are made from a mixture of carbon and a binding material. They are cost-effective and suitable for low-power applications but may have higher noise levels and lower stability compared to other types.

2. **Metal Film**: Metal film resistors are made by depositing a thin layer of metal onto a ceramic substrate. They offer better stability, lower noise, and tighter tolerances, making them ideal for precision applications in automotive electronics.

3. **Wire Wound**: Wire wound resistors are constructed by winding a metal wire around a core. They can handle high power ratings and are often used in applications requiring high precision and stability.

B. Impact of Material on Performance and Durability

The choice of material affects not only the electrical performance of the resistor but also its durability and reliability in harsh automotive environments. For instance, metal film resistors tend to perform better under varying temperatures and humidity levels compared to carbon composition resistors.

C. Environmental Considerations

Automotive resistors must withstand extreme conditions, including high temperatures, moisture, and exposure to chemicals. Therefore, selecting materials that offer heat resistance and moisture protection is crucial for ensuring long-term reliability.

V. Packaging and Form Factors

A. Overview of Common Packaging Types

Automotive resistors come in various packaging types, including:

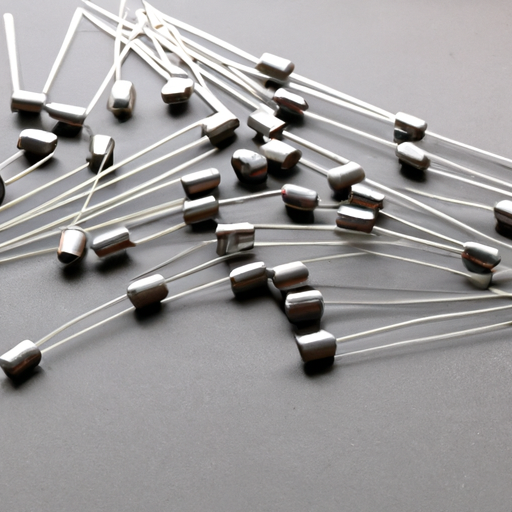

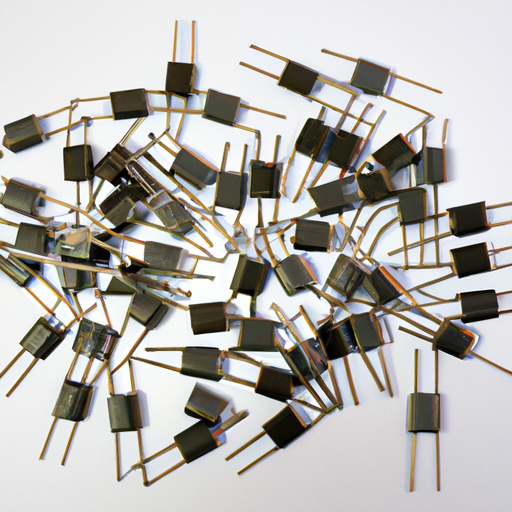

1. **Through-Hole Resistors**: These resistors have leads that are inserted into holes on a printed circuit board (PCB) and soldered in place. They are commonly used in traditional automotive designs.

2. **Surface-Mount Resistors**: These resistors are mounted directly onto the surface of a PCB, allowing for more compact designs and improved performance in modern vehicles.

B. Importance of Form Factor in Automotive Design

The form factor of a resistor is crucial in automotive design, as space and weight are often limited. Surface-mount resistors are preferred in many applications due to their smaller size and lighter weight, which contribute to overall vehicle efficiency.

C. Considerations for Space and Weight in Automotive Applications

As vehicles become more compact and efficient, the need for smaller and lighter components, including resistors, becomes increasingly important. Engineers must consider the form factor of resistors to optimize space and weight without compromising performance.

VI. Reliability and Durability

A. Factors Affecting Reliability in Automotive Environments

Automotive resistors must be able to withstand various environmental factors, including:

1. **Vibration and Shock Resistance**: Vehicles experience constant vibrations and shocks, which can lead to mechanical failure in components. Resistors must be designed to endure these conditions.

2. **Temperature Extremes**: Automotive environments can experience extreme temperatures, from freezing cold to scorching heat. Resistors must maintain performance across this range.

3. **Moisture and Corrosion Resistance**: Exposure to moisture and corrosive substances can lead to failure. Resistors must be designed with materials that resist corrosion and moisture ingress.

B. Testing and Standards for Automotive Resistors

To ensure reliability and safety, automotive resistors must comply with industry standards, such as AEC-Q200. This standard outlines rigorous testing procedures to evaluate the performance and reliability of components in automotive applications.

VII. Applications of Automotive Resistors

A. Role in Electronic Control Units (ECUs)

Automotive resistors play a vital role in ECUs, which manage various vehicle functions, including engine control, transmission, and safety systems. Resistors help regulate signals and ensure accurate communication between components.

B. Use in Sensors and Actuators

Resistors are integral to the functioning of sensors and actuators, which monitor and control various vehicle systems. For example, thermistors are used in temperature sensors, while variable resistors are used in throttle position sensors.

C. Applications in Lighting and Infotainment Systems

In lighting systems, resistors help control the brightness of LEDs and other lighting elements. In infotainment systems, they are used in audio controls and signal processing.

D. Importance in Electric and Hybrid Vehicles

As electric and hybrid vehicles become more prevalent, the demand for reliable and efficient resistors increases. These vehicles often require specialized resistors to manage high-voltage systems and ensure safe operation.

VIII. Future Trends in Automotive Resistors

A. Advances in Materials and Technology

The automotive industry is continually evolving, with advancements in materials and technology leading to the development of more efficient and reliable resistors. Innovations such as nanomaterials and advanced ceramics may enhance performance and durability.

B. Impact of Electric Vehicles on Resistor Design

The rise of electric vehicles (EVs) is driving changes in resistor design, as these vehicles require components that can handle higher voltages and currents. Resistors must be optimized for performance in high-power applications.

C. Emerging Applications and Innovations

As automotive technology advances, new applications for resistors are emerging, including their use in autonomous vehicles and advanced driver-assistance systems (ADAS). Resistors will play a crucial role in ensuring the reliability and safety of these systems.

IX. Conclusion

In conclusion, automotive resistors are critical components that ensure the proper functioning of various electrical systems in vehicles. Understanding their types, key characteristics, material composition, packaging, reliability, and applications is essential for anyone involved in the automotive industry. As technology continues to evolve, the importance of automotive resistors will only grow, making it crucial to stay informed about the latest trends and innovations in this field.

X. References

A comprehensive list of sources and further reading materials can be provided to support the information presented in this article, ensuring readers have access to additional resources for deeper exploration of automotive resistors and their characteristics.