What are the popular and hot-selling cold-formed embedded trough product types in large quantities in stock?

What are the Popular and Hot-Selling Cold-Formed Embedded Trough Product Types in Large Quantities in Stock?

I. Introduction

Cold-formed embedded troughs are essential components in various industries, providing structural support and facilitating the organization of electrical, telecommunications, and HVAC systems. These products are manufactured through a cold-forming process, which involves shaping metal sheets into desired profiles without the application of heat. This method not only enhances the material's strength but also allows for precise dimensions and intricate designs. In this article, we will explore the popular and high-demand types of cold-formed embedded troughs, their applications, and the factors contributing to their popularity in the market.

II. Understanding Cold-Formed Embedded Troughs

A. Explanation of Cold-Forming Process

Cold-forming is a manufacturing technique that involves shaping metal at room temperature. This process offers several benefits, including improved mechanical properties, reduced material waste, and the ability to create complex shapes. Unlike hot-forming, which can alter the material's properties due to high temperatures, cold-forming maintains the integrity of the metal, resulting in stronger and more durable products.

B. Applications of Embedded Troughs

Cold-formed embedded troughs find applications across various sectors:

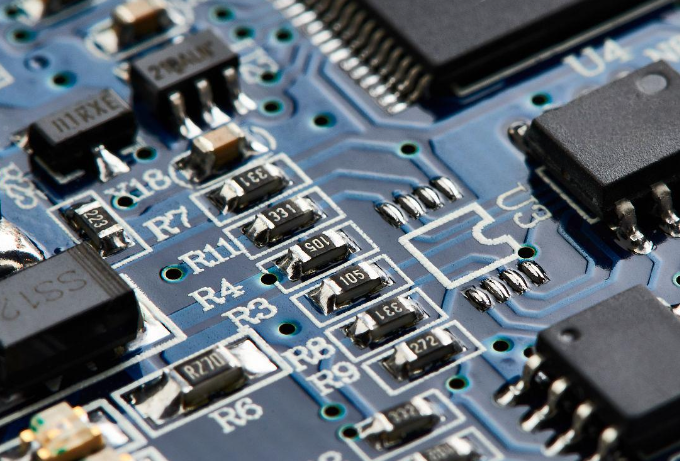

1. **Construction and Infrastructure**: These troughs are used in building frameworks, providing support for electrical and plumbing systems.

2. **Electrical and Telecommunications**: They serve as conduits for wiring and cables, ensuring organized and safe installations.

3. **HVAC Systems**: Embedded troughs help in routing ductwork and piping, optimizing space and improving system efficiency.

III. Popular Types of Cold-Formed Embedded Trough Products

A. Standard Embedded Troughs

Standard embedded troughs are the most commonly used type in the market. They are designed to meet general specifications and are available in various sizes and materials, including steel and aluminum. These troughs are widely utilized in construction projects, providing a reliable solution for housing electrical and plumbing systems.

B. Custom Embedded Troughs

For projects with specific requirements, custom embedded troughs are tailored to meet unique needs. These products can be designed to accommodate particular dimensions, load capacities, and environmental conditions. Industries such as telecommunications and specialized construction often rely on custom solutions to ensure optimal performance.

C. Pre-Insulated Troughs

Pre-insulated troughs offer significant advantages, particularly in HVAC applications. The insulation helps maintain temperature control, reducing energy consumption and improving system efficiency. These products are increasingly popular in industries focused on sustainability and energy efficiency, making them a hot-selling item in the market.

D. Modular Trough Systems

Modular trough systems are designed for easy assembly and disassembly, making them ideal for large-scale projects. Their modular nature allows for flexibility in design and installation, accommodating changes in project scope or layout. These systems are particularly favored in construction and infrastructure projects where adaptability is crucial.

IV. Factors Contributing to Popularity and High Sales

A. Durability and Longevity

One of the primary reasons for the popularity of cold-formed embedded troughs is their durability. Made from high-quality materials, these products resist environmental factors such as moisture, corrosion, and temperature fluctuations. Their longevity translates to cost-effectiveness over time, as they require less frequent replacement and maintenance.

B. Versatility and Customization

Cold-formed embedded troughs are highly versatile, making them suitable for a wide range of applications. Their ability to be customized ensures that they can meet specific project requirements, whether in construction, telecommunications, or HVAC systems. This adaptability enhances their appeal to contractors and project managers.

C. Ease of Installation

The ease of installation is another significant factor driving the demand for cold-formed embedded troughs. These products are designed for quick and straightforward installation, saving time and labor costs for contractors. Their compatibility with existing systems further simplifies the installation process, making them a preferred choice in many projects.

D. Compliance with Industry Standards

Adhering to industry standards and regulations is crucial for any construction or installation project. Cold-formed embedded troughs are manufactured to meet these standards, ensuring safety and reliability. This compliance not only boosts market demand but also instills confidence in consumers regarding the quality of the products.

V. Market Trends and Consumer Preferences

A. Growing Demand in Construction and Infrastructure

The construction and infrastructure sectors are experiencing significant growth, driven by urban development and investments in public infrastructure. As cities expand and modernize, the demand for reliable and efficient embedded troughs continues to rise. This trend is expected to persist, further boosting the sales of cold-formed products.

B. Sustainability and Eco-Friendly Products

There is a growing emphasis on sustainability and eco-friendly products across industries. Consumers are increasingly seeking materials that minimize environmental impact. Cold-formed embedded troughs, particularly pre-insulated options, align with this trend by promoting energy efficiency and reducing waste. This shift towards environmentally responsible materials is influencing purchasing decisions and driving sales.

C. Technological Advancements

Technological advancements in manufacturing processes are also shaping the market for cold-formed embedded troughs. Innovations such as automation and smart technologies are enhancing production efficiency and product performance. As manufacturers adopt these technologies, they can offer higher-quality products that meet the evolving needs of consumers.

VI. Conclusion

In summary, cold-formed embedded troughs are vital components in various industries, offering durability, versatility, and ease of installation. The popularity of standard, custom, pre-insulated, and modular trough systems reflects the diverse needs of consumers and the growing demand in construction and infrastructure. Factors such as durability, customization, compliance with industry standards, and a focus on sustainability contribute to their high sales.

As the market continues to evolve, understanding consumer preferences and market trends will be crucial for manufacturers and suppliers. The future outlook for cold-formed embedded trough products remains positive, with increasing opportunities for innovation and growth in response to the demands of modern construction and infrastructure projects.

VII. References

1. Industry reports on cold-formed products and market trends.

2. Studies on the benefits of cold-forming processes.

3. Articles discussing the applications of embedded troughs in various sectors.

4. Resources on sustainability in construction materials and practices.

This comprehensive overview of cold-formed embedded troughs highlights their significance in today's market, providing valuable insights for industry professionals and consumers alike.