Similar recommendations for varistor components

Similar Recommendations for Varistor Components

I. Introduction

A. Definition of Varistors

Varistors, or voltage-dependent resistors, are crucial components in electronic circuits, designed to protect sensitive devices from voltage spikes. They function by changing their resistance based on the voltage applied across them. When the voltage exceeds a certain threshold, the varistor's resistance decreases dramatically, allowing it to absorb excess energy and prevent damage to downstream components. This unique property makes varistors essential in various applications, particularly in surge protection.

B. Purpose of the Article

The purpose of this article is twofold: first, to provide recommendations for selecting the right varistor components for specific applications, and second, to educate readers on the different types of varistors available and their respective uses. Understanding these components can significantly enhance the reliability and safety of electronic devices.

II. Understanding Varistors

A. What is a Varistor?

Varistors operate on the principle of non-linear resistance. They are designed to protect circuits from transient voltage spikes, such as those caused by lightning strikes or power surges. The most common types of varistors include Metal Oxide Varistors (MOVs) and Zener diodes, each with distinct characteristics and applications.

B. Key Characteristics

When selecting a varistor, several key characteristics must be considered:

1. **Voltage Rating**: This indicates the maximum voltage the varistor can withstand without conducting significantly. Selecting the correct voltage rating is critical to ensure effective protection.

2. **Clamping Voltage**: This is the maximum voltage that the varistor will allow to pass through during a surge. A lower clamping voltage provides better protection but may also lead to more frequent activation.

3. **Energy Absorption Capacity**: This refers to the amount of energy the varistor can absorb during a surge. It is essential to match this capacity to the expected surge energy in the application.

4. **Response Time**: Varistors have a fast response time, typically in the nanosecond range, which is crucial for protecting sensitive electronics.

C. Applications of Varistors

Varistors are widely used in various applications, including:

1. **Surge Protection**: They are commonly found in power strips, surge protectors, and circuit boards to safeguard against voltage spikes.

2. **Voltage Regulation**: Varistors can help maintain stable voltage levels in circuits, ensuring consistent performance.

3. **Circuit Protection**: In industries such as telecommunications, automotive, and consumer electronics, varistors play a vital role in protecting sensitive components from overvoltage conditions.

III. Types of Varistors

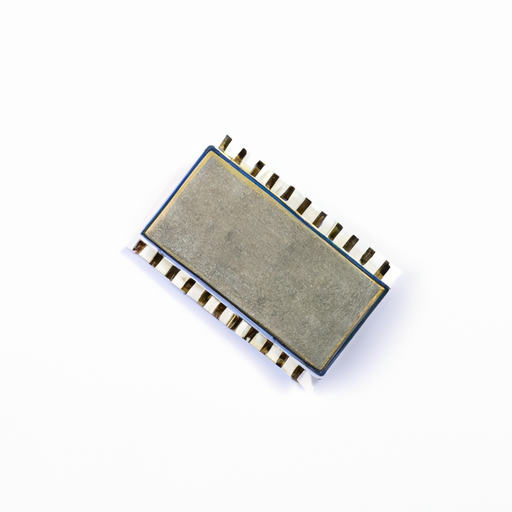

A. Metal Oxide Varistors (MOVs)

MOVs are the most common type of varistor, made from a ceramic material that contains zinc oxide. They are known for their high energy absorption capacity and are widely used in surge protection applications. MOVs are effective in clamping high voltage spikes, making them suitable for power supply circuits and industrial equipment.

B. Zener Diodes

Zener diodes are another type of voltage-dependent device that can function similarly to varistors. They are designed to maintain a constant voltage across their terminals when reverse-biased. While Zener diodes are excellent for voltage regulation, they are not as effective as MOVs for high-energy surge protection. They are often used in low-power applications where precise voltage regulation is required.

C. Silicon Carbide Varistors

Silicon carbide varistors are known for their ability to operate in high-voltage environments. They offer advantages such as high thermal stability and resistance to electrical breakdown. These varistors are ideal for applications in power electronics and renewable energy systems, where high voltage and temperature conditions are prevalent.

D. Polymer Varistors

Polymer varistors are made from conductive polymer materials and are known for their lightweight and compact design. They are particularly useful in consumer electronics, where space is limited. Polymer varistors offer good performance in terms of clamping voltage and energy absorption, making them suitable for a variety of applications.

IV. Factors to Consider When Selecting Varistors

A. Voltage Ratings

Selecting the correct voltage rating is crucial for effective protection. The voltage rating should be higher than the maximum operating voltage of the circuit but lower than the maximum clamping voltage. This ensures that the varistor activates only during a surge, protecting the circuit without interfering with normal operation.

B. Energy Absorption Capacity

Understanding the energy ratings of varistors is essential for matching them to application needs. The energy absorption capacity should be greater than the expected surge energy to prevent failure during a surge event. Manufacturers often provide datasheets with energy ratings, which can guide selection.

C. Clamping Voltage

The clamping voltage significantly affects circuit performance. A lower clamping voltage provides better protection but may lead to more frequent activation, potentially causing wear over time. It is essential to balance protection needs with the potential for nuisance tripping.

D. Environmental Considerations

Environmental factors such as operating temperature range, humidity, and mechanical stress can impact varistor performance. Selecting a varistor that can withstand the specific conditions of the application is vital for long-term reliability.

V. Recommendations for Varistor Components

A. Popular Varistor Brands and Models

Several manufacturers are known for producing high-quality varistors. Some leading brands include:

1. **Vishay**: Known for a wide range of MOVs suitable for various applications.

2. **Littelfuse**: Offers a variety of varistors with different voltage ratings and energy absorption capacities.

3. **TE Connectivity**: Provides polymer varistors ideal for consumer electronics.

When selecting a model, consider the specific requirements of your application, such as voltage rating and energy absorption capacity.

B. Comparison of Varistor Types

Each type of varistor has its pros and cons:

MOVs: High energy absorption, suitable for high-voltage applications, but can degrade over time with repeated surges.

Zener Diodes: Excellent for voltage regulation, but not ideal for high-energy surges.

Silicon Carbide Varistors: Great for high-voltage environments, but may be more expensive.

Polymer Varistors: Lightweight and compact, but may have lower energy absorption compared to MOVs.

C. Sourcing Varistors

Varistors can be sourced from various suppliers, both online and locally. Websites like Digi-Key, Mouser, and Newark offer a wide selection of varistors. For bulk purchasing, consider contacting manufacturers directly for better pricing and availability.

VI. Case Studies

A. Industrial Applications

In manufacturing, varistors are often used to protect sensitive equipment from voltage spikes caused by machinery. For example, a factory that uses large motors may experience voltage transients during startup. Implementing MOVs in the power supply circuit can significantly enhance equipment longevity and safety, reducing downtime and maintenance costs.

B. Consumer Electronics

In home appliances, varistors are commonly used to protect against voltage surges from the power grid. A case study involving a washing machine showed that incorporating a varistor improved performance and reliability, reducing the risk of damage from power surges and extending the appliance's lifespan.

C. Automotive Applications

In automotive electronics, varistors play a critical role in protecting sensitive components from voltage spikes caused by the vehicle's electrical system. For instance, varistors are used in electronic control units (ECUs) to ensure safety and regulatory compliance, enhancing the overall reliability of automotive systems.

VII. Conclusion

A. Recap of Key Points

Selecting the right varistor is essential for protecting electronic circuits from voltage spikes. Understanding the different types of varistors, their characteristics, and the factors to consider when selecting them can significantly impact the performance and reliability of electronic devices.

B. Future Trends in Varistor Technology

As technology advances, we can expect innovations in varistor design and materials. Future trends may include the development of more compact and efficient varistors, improved energy absorption capabilities, and enhanced environmental resistance. These advancements will likely have a positive impact on electronic design and safety, further solidifying the role of varistors in modern electronics.

VIII. References

1. Vishay Intertechnology. (2023). Varistor Products. Retrieved from [Vishay website](https://www.vishay.com)

2. Littelfuse. (2023). Varistor Selection Guide. Retrieved from [Littelfuse website](https://www.littelfuse.com)

3. TE Connectivity. (2023). Polymer Varistors. Retrieved from [TE Connectivity website](https://www.te.com)

4. Various academic papers and articles on varistor technology and applications.

This comprehensive overview of varistor components provides valuable insights for engineers, designers, and hobbyists looking to enhance the reliability and safety of their electronic circuits.